Engrave Inside Glass Block - Business Opportunity

GK

This article was inspired by a largely visual post at the Laser Freedom Facebook Post. The end product was so nice but more information is needed to really understand the topic, so we will dive a little deeper here.

First I will give a link to the laser that will do this, consideration of tool price is always important if you are thinking of this in a business opportunity.

Https://laserinfo.us/GlassBlock

Please Read Disclosure at the bottom of the article about links.

As laser businesses look to expand their offerings, one niche that’s been getting attention is laser marking inside glass blocks. The appeal is obvious—stunning, 3D-like images suspended within crystal-clear blocks make for impressive awards, memorials, gifts, and promotional items. But is it a smart investment or just another flashy add-on?

Let’s break down the pros and cons of laser marking inside glass blocks so you can decide whether it's a good fit for your laser engraving business.

✅ The Good: Why Glass Block Laser Engraving Is Gaining Popularity

1. High-Perceived Value Product

Engraved glass blocks command premium prices. Customers view them as elegant and durable, ideal for high-end gifts, corporate recognition, and artistic pieces. A single 3D-engraved glass block can retail for anywhere from $40 to several hundred dollars.

2. Differentiation from Competitors

Not everyone offers internal glass engraving—especially true sub-surface laser engraving—so adding this service can set your business apart. It's a great conversation starter and an effective upsell at trade shows or in-store displays.

3. Perfect for Personalization

Names, logos, dates, or even 3D scans can be etched into the center of the block, making the product personal and memorable. These make popular wedding gifts, baby keepsakes, or retirement awards.

4. Compatibility with Galvo and Fiber Lasers (in Some Cases)

If you already own a galvo-based laser with the right specs and focusing system, you may not need to buy a completely new setup to get started—though results vary greatly depending on equipment.

Sample Picture / The results below.

❌ The Bad: What You Need to Know Before Jumping In

1. Not All Lasers Can Do It

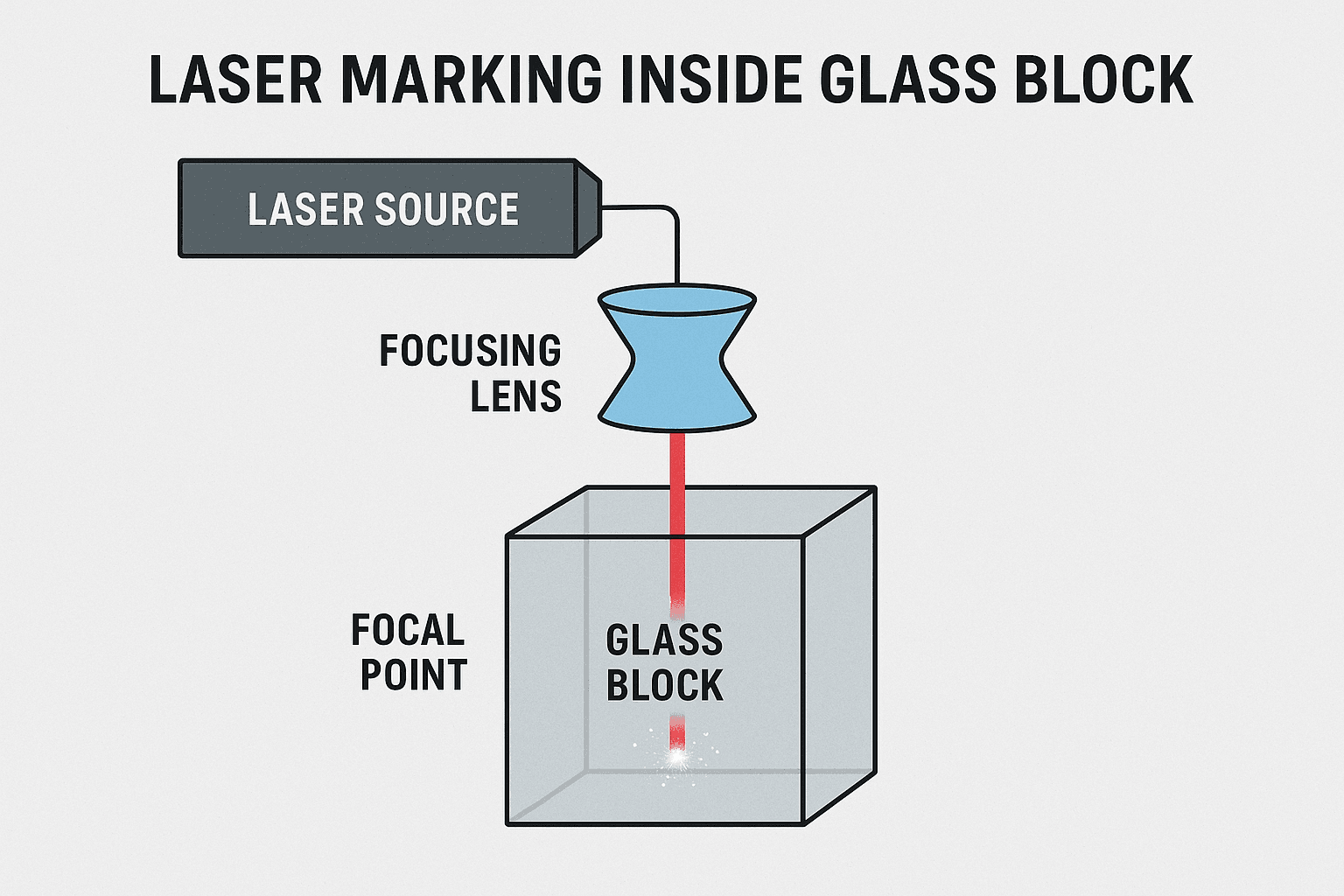

True 3D sub-surface glass marking typically requires a specialized diode-pumped solid-state (DPSS) laser—not your standard CO2 or fiber laser. These lasers focus energy inside the block, creating tiny fractures (called “bubbles”) to form the design. That means a steep learning curve and a possible $10K–$50K investment in new hardware.

2. Limited Material Options

You must use optically pure glass or crystal blocks—cheap glass or anything with air bubbles, color tint, or imperfections can crack or cause bad engraving. These materials can be costly and require careful handling and sourcing.

3. Time-Consuming Setup and Design

Sub-surface engraving—especially in 3D—requires very specific design files (often point cloud data or STL models). Getting these right takes time, especially if you’re converting photos or scans. Your average LightBurn file won’t cut it here.

4. Speed and Production Bottlenecks

Compared to standard surface engraving, laser marking inside a block is slow. Larger or more complex designs can take several minutes per block, limiting how many units you can process in a day. Automation is rare unless you go very high-end.

5. Cracking and Waste

Glass blocks are unforgiving. Improper laser power, wrong focus depth, or even a dirty lens can result in cracked material—and that means wasted inventory and profit loss.

🧠 Final Thoughts: Should You Add Glass Block Marking?

If you’re a high-end engraver already working with awards, corporate gifts, or personalized art—and you're ready to invest in specialized equipment and training—then adding laser-marked glass blocks may be a smart strategic move. Or maybe you are like me and just know you can do it and may burn up some glass, but realize there is a learning curve.

But if you’re working on tight margins, selling to hobbyists or mass-producing quick-turnaround items, this niche might be more hassle than it’s worth—at least until the technology becomes more accessible.

DISCLOSURE: No Staff Member at Freedom Laser has a relationship with the company featured in the link, HaoTian Laser. We aid to share two things. TRUST BUT VERIFY. Do not believe anything we say! Prove it. This will lead to our second goal. GET THE RIGHT TOOL FOR THE JOB. We welcome comments.