A 10W UV Laser, a 5W UV Laser, and a Bar Glass Walk into a Business Plan…

GK

A 10W UV Laser, a 5W UV Laser, and a Bar Glass Walk into a Business Plan…

If you’re shopping for a UV laser right now, you’ve probably noticed something weird: in some cases, a 5 watt UV and a 10 watt UV are not that far apart in price. That’s the situation with machines like a 5W unit from a big consumer brand versus a 10W unit from a more engineering‑driven company. The 5W can absolutely “do the job” — it will mark glass, plastics, and all the usual suspects — but it will take significantly more time to do the same work a 10W can finish in one pass or at a higher speed. And time, when you’re running a business, is not free.

Independent comparisons of 5W and 10W UV engravers show the same pattern over and over: the 10W unit can complete identical jobs in less than half the time once you match depth and quality, with some tests reporting roughly 2×–4× speed gains in real engraving scenarios. In other words, you can buy the slower machine now, or wait a bit longer, spend a bit more, and buy back a lot of your future evenings.

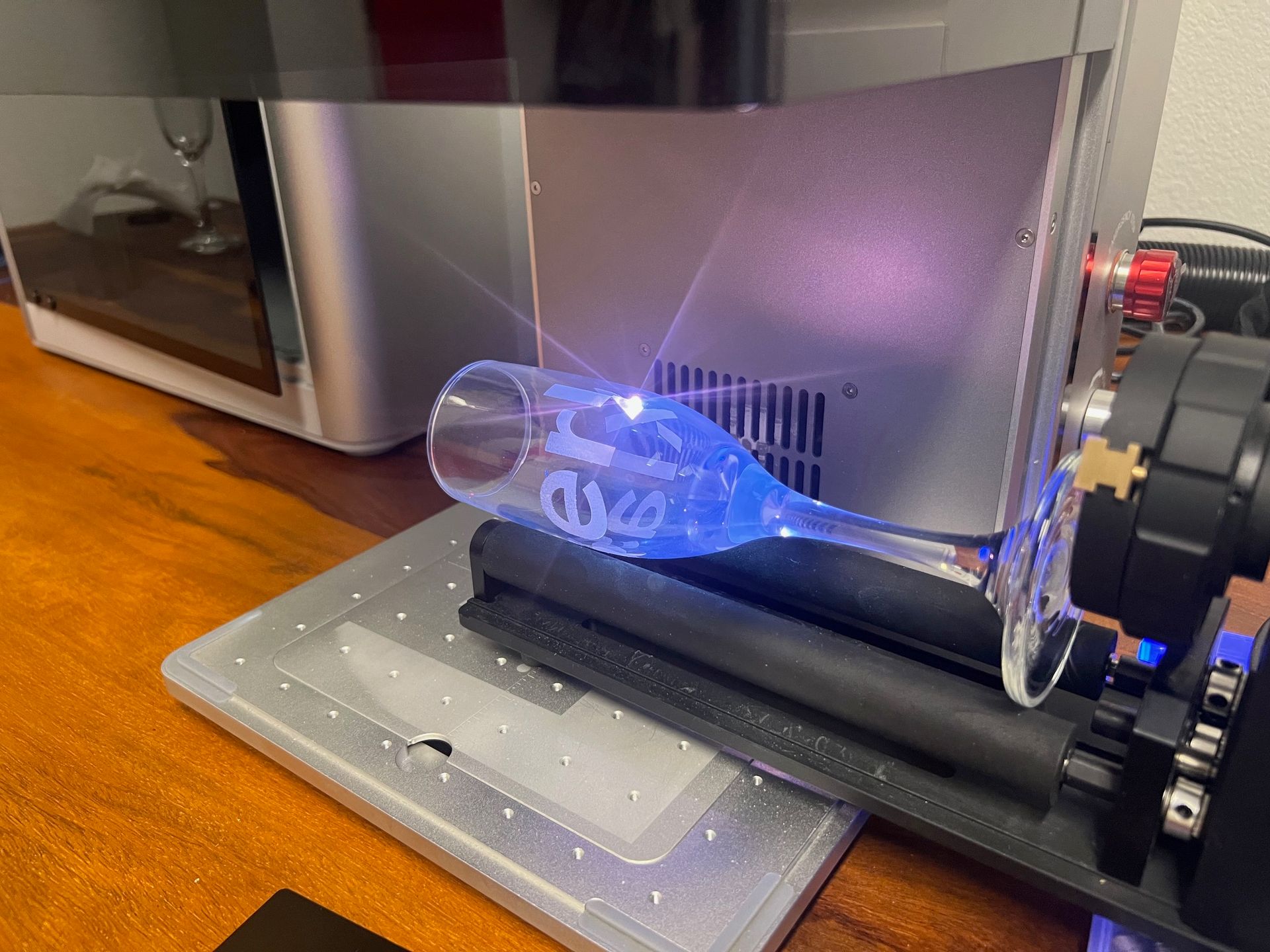

This article walks through a simple business plan built around one of the most boring objects on earth — a 16 oz bar glass — and shows how that extra power translates into payback time, capacity, and sanity for someone starting an engraving company with a UV laser.

Step 1: The Dollar‑Store Bar Glass as a Business Model

Imagine the classic 16 oz pint glass you can grab at a dollar store or wholesale supplier.

Assumptions:

As you consider these number you could of course cut labor time in half if you had more than one machine. But in fairness all these numbers are focused on one machine. I think most people would buy one laser to start.

The machine I like the best is linked here... (Disclosure I am not sponsored by anyone and I have yet to buy a UV Laser this is part of my research)

Glass cost: 1.50 dollars per blank

Breakage (pushing speed, learning curve, occasional “oops”): 10%

Engraving time on a 10W UV: 5 minutes per glass for a clean brewery logo

Labor rate (your time or a helper): 15 dollars per hour

Wholesale selling price to a bar/brewery: 6 dollars per finished glass

First, bake the breakage into the glass cost. If 10% of glasses don’t survive, only 90% become sellable product:

Effective glass cost=$1.500.90≈$1.67Effective glass cost=0.90$1.50≈$1.67So each successful engraved glass really carries about 1.67 dollars of glass cost.

Time per glass: 5 minutes.

5 minutes=560≈0.0833 hours5 minutes=605≈0.0833 hoursLabor per glass at 15 dollars/hour:

Labor=15×0.0833≈$1.25Labor=15×0.0833≈$1.25Total direct cost per finished glass:

Total cost≈1.67 (glass)+1.25 (labor)≈$2.92Total cost≈1.67 (glass)+1.25 (labor)≈$2.92Round it: about 3 dollars in direct cost per engraved bar glass.

At a low wholesale price of 6 dollars:

Revenue: 6

Direct cost: ≈ 3

Gross profit per glass: ≈ 3 dollars

No magic. Just a cheap glass, some UV time, and a 3‑dollar margin that starts to add up when you repeat it a few thousand times.

Step 2: Paying Off a 10W UV at 7,500 Dollars

Now introduce the machine:

10W UV laser cost: 7,500 dollars (a reasonable ballpark for a solid 10W galvo UV setup)

How many bar glasses at 3 dollars profit each to pay for that?

Glasses to break even=7,5003=2,500Glasses to break even=37,500=2,500So, you’d need to engrave and sell about 2,500 bar glasses at these assumptions to cover the cost of the 10W machine.

How long is that in actual laser time?

Each glass takes 5 minutes on the 10W:

2,500×560≈208.3 hours2,500×605≈208.3 hoursConvert to 8‑hour “workdays” of beam time:

208.38≈26 days8208.3≈26 daysSo you’re looking at roughly 26 eight‑hour days of actual engraving time to pay off the machine in gross profit, assuming you can find the customers and keep the jobs flowing.

Is that a lot of glasses? Yes. Is it impossible over a year or two of part‑time work? Not at all.

Step 3: Where the 5W UV Starts Falling Behind

Now, bring in the 5W vs 10W question.

Real‑world tests comparing 5W and 10W UV engravers consistently show that the 10W can do the same work at a significantly higher speed or in fewer passes:

On some metals, a 5W UV needed around four times longer than a 10W to reach similar engraving depth.

On tempered glass, a 10W UV was measured engraving more than twice as fast as the 5W at comparable quality.

General buyer guides and reviews boil this down to a practical rule: a 10W UV doesn’t just “hit harder,” it finishes the same designs substantially faster, while 5W units can only match the result by slowing down or adding passes.

If you use a conservative 2× speed factor for planning, the 10W’s 5‑minute job becomes an 8–10 minute job on a 5W once you dial in the same quality.

Take 10 minutes as a simple worst‑case comparison:

10W at 5 minutes:

Time = 0.0833 hours

Labor = 15 × 0.0833 ≈ 1.25 dollars

5W at 10 minutes:

Time = 0.1667 hours

Labor = 15 × 0.1667 ≈ 2.50 dollars

Difference in labor per glass: 1.25 dollars more burned every single time you let the 5W grind out the same logo.

At the same 6‑dollar selling price:

10W profit per glass ≈ 6 − (1.67 + 1.25) ≈ 3.08 dollars

5W profit per glass ≈ 6 − (1.67 + 2.50) ≈ 1.83 dollars

Now the 5W still “works,” but:

You earn ~3.08 dollars per glass on the 10W

You earn ~1.83 dollars per glass on the 5W

To pay off the same 7,500‑dollar investment:

10W:

7,500/3.08≈2,435 glasses7,500/3.08≈2,435 glasses5W:

7,500/1.83≈4,098 glasses7,500/1.83≈4,098 glassesAnd time:

10W: ~2,435 × 5 minutes ≈ 203 hours ≈ 25.4 days

5W: ~4,098 × 10 minutes ≈ 683 hours ≈ 85.4 days

Same bar glass. Same logo. Same selling price.

The “cheaper” 5W UV can easily take more than three times as many workdays of beam time to claw back the same machine cost, once you count the extra minutes hiding inside every job.

This is why it can make more sense to wait, save, and buy the 10W: you’re not just buying watts, you’re buying back months of your life.

Step 4: “What If I Add a Second Machine?”

Here’s where the “more lasers, less calendar” concept shows up.

For the 10W:

About 2,500 glasses to pay off the 7,500‑dollar machine at 3 dollars profit each (using the simpler 5‑minute example).

About 208 hours of engraving time.

About 26 eight‑hour days on one machine.

With two 10W machines running:

Total glasses are still 2,500.

But the engraving time is split across two units.

Each machine only sees about 104 hours of work to reach the same total output — about 13 eight‑hour days each.

In other words:

One 10W: 26 days of beam time

Two 10W: 13 days each for the same revenue

That’s down the road, of course. Everyone starts with one machine. The point is that once you prove the math with a 10W, scaling with more 10W machines follows the same logic — and the 5W remains the one that makes you wait around.

Step 5: Moving from Bar Glasses to “Real Money” Items

Bar glasses are a good sandbox:

Low risk

Easy to source

Easy to sell wholesale in batches

But nobody buys a UV laser just to live on 6‑dollar glasses forever. The natural next step is higher‑value, personalized items where your time is better paid:

Flasks and gift sets

Whiskey glasses in presentation boxes

Decanters and premium glassware

Small high‑value items like metal cards, tags, watch backs, and tech accessories

Example: a personalized decanter set

Assume:

Blank decanter cost: 20–30 dollars

Retail price for an engraved set: 80–150 dollars

Net profit per piece after material and labor: 30+ dollars (very realistic in many markets)

If a decanter job nets 30 dollars:

Pieces to pay off a 7,500 dollar machine=7,50030=250Pieces to pay off a 7,500 dollar machine=307,500=250So while the humble pint glass might need 2,500 units to pay for the machine, a well‑positioned decanter line could do it in about 250 units.

And here again, the 10W vs 5W story repeats:

A 10W UV can finish those engraving passes faster and cleaner, especially on glass and coatings.

A 5W can emulate the result — at the cost of more time, more risk with heat buildup, and more lost hours on every premium piece.

On high‑margin items, every extra minute is your margin evaporating.

Step 6: Why This All Started with “Is UV Even Worth It?”

Stepping back, this whole exercise started with a simple question:

“Is a UV machine, especially a 10W UV, really a solid investment for someone trying to start an engraving business?”

The short version, using the bar glass as a test case:

Yes, a 10W UV can pay for itself on low‑margin items like pint glasses if you can generate steady orders.

The math gets dramatically better as you move into higher‑value products: flasks, sets, decanters, specialty glass, and small high‑value marks.

The extra power of a 10W compared with a 5W doesn’t just make for nicer spec sheets — it directly reduces time per job and the number of days you’re glued to the machine.

You might have to wait longer and save more to buy the 10W instead of the near‑priced 5W. But once the work starts flowing, the 10W behaves like a partner that actually wants you to go home on time. The 5W will get the job done… eventually… while the clock keeps ticking and your profit per hour quietly shrinks.

If you take nothing else from this: run your numbers. Use your wage, your glass cost, your pricing. Swap in your favorite machine’s price tag. The formulas are simple, the logic is straightforward, and once you see the difference in total hours and total units, the decision between “almost‑the‑same‑price” 5W and 10W UV machines stops being emotional and starts being math.

We are not Laser Experts and when we say something it is based on researh, we want to share out points of reference. Everyone has to do their own research to get the right tool for their job. If you disagree with something we wrote please reach out to us. We only want to share the best of information.

JOIN US ON FACEBOOK Click Here

Below are links that we either referenced or gathered information from.

Hobby Laser Cutters – “5W vs 10W ComMarker Omni 1 UV Laser: Which One Is Right for You?”

https://hobbylasercutters.com/5w-vs-10w-uv-laser-engraver/

The Maker’s Chest – “5W vs 10W UV Laser – Which Power Level is Right for You?”

https://themakerschest.com/blogs/laser-engravers/5w-vs-10w-uv-laser-which-power-level-is-right-for-you

ComMarker Blog – “Which UV Laser Engraver Should You Choose: ComMarker Omni …”

https://blog.commarker.com/archives/53213

YouTube – “Don’t Buy a UV LASER Until You Watch This – 5W vs 10W …”

https://www.youtube.com/watch?v=AZwsxqzUZDE

YouTube – “How Much Better Than The 5W? UV Laser Engraver Review and Test”

https://www.youtube.com/watch?v=LH6GypFHd6Y

YouTube – “5W vs 10W Omni X – Is the Upgrade Worth It? Side-by-Side …”

https://www.youtube.com/watch?v=WPS9axb5g7I