K9 Glass - The type they use in UV Laser Blocks

GK

Date: November 21, 2025

All of the information below reflects what I found before I made a purchase decision. Specifications, pricing, features, safety requirements, and performance can change at any time. Please double-check the manufacturers’ official websites before buying anything. I will never claim to be an expect, things change to fast.

K9 Glass and the UV Market Explosion

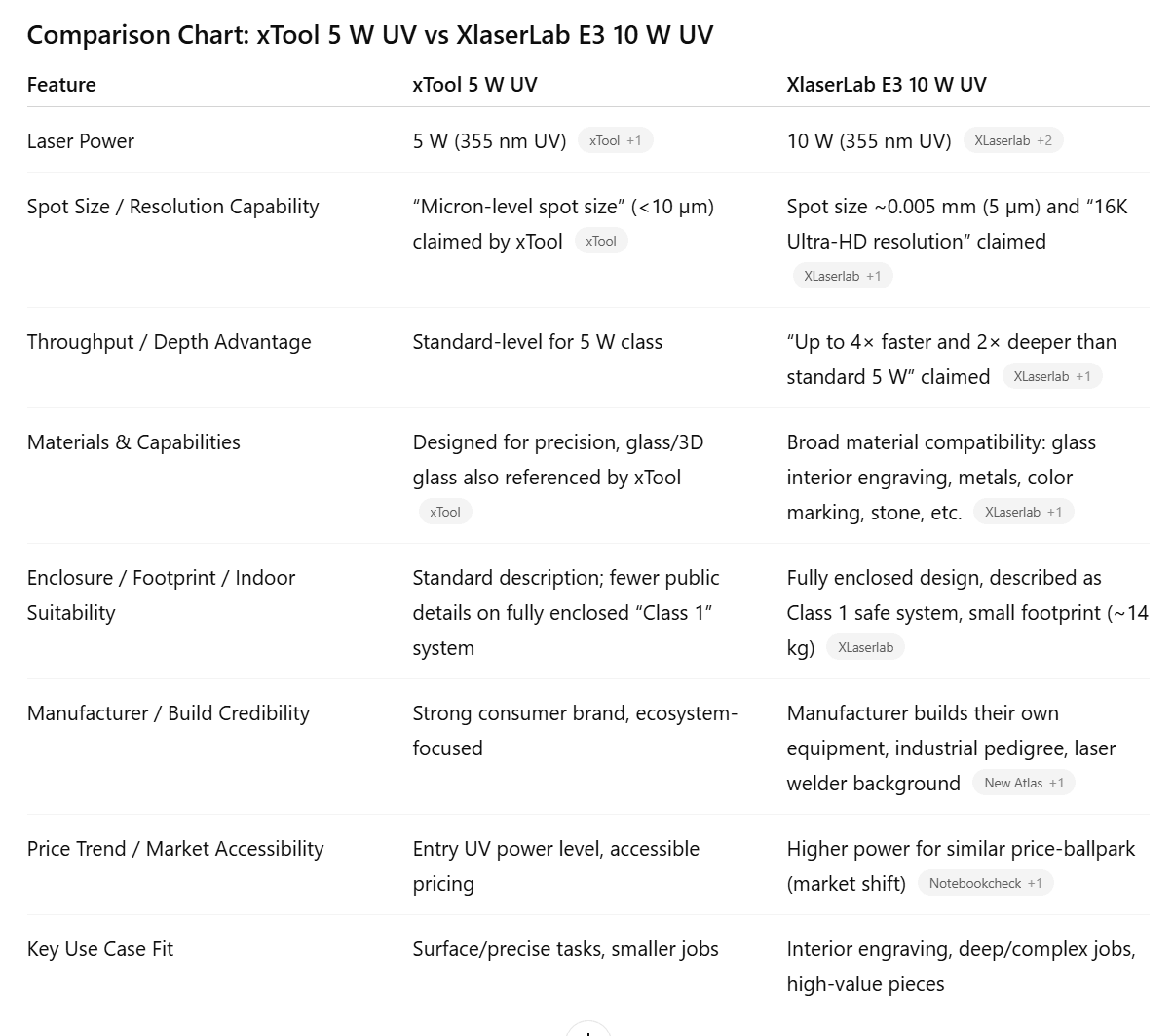

I’ve finally reached the point where my laser journey is taking its next big step: I’m going to buy a UV laser. Not “thinking about it.” Not “researching it endlessly.” No — the purchase is happening. And as the market continues to shift at warp speed, I realized that my decision has narrowed itself down to just two serious contenders: the brand-new xTool UV and the XlaserLab E3. Both are 355 nm ultraviolet engravers, both are aimed at the exploding prosumer market, and both are suddenly priced low enough that normal people can consider buying them without refinancing the house. But that’s about where the similarities end.

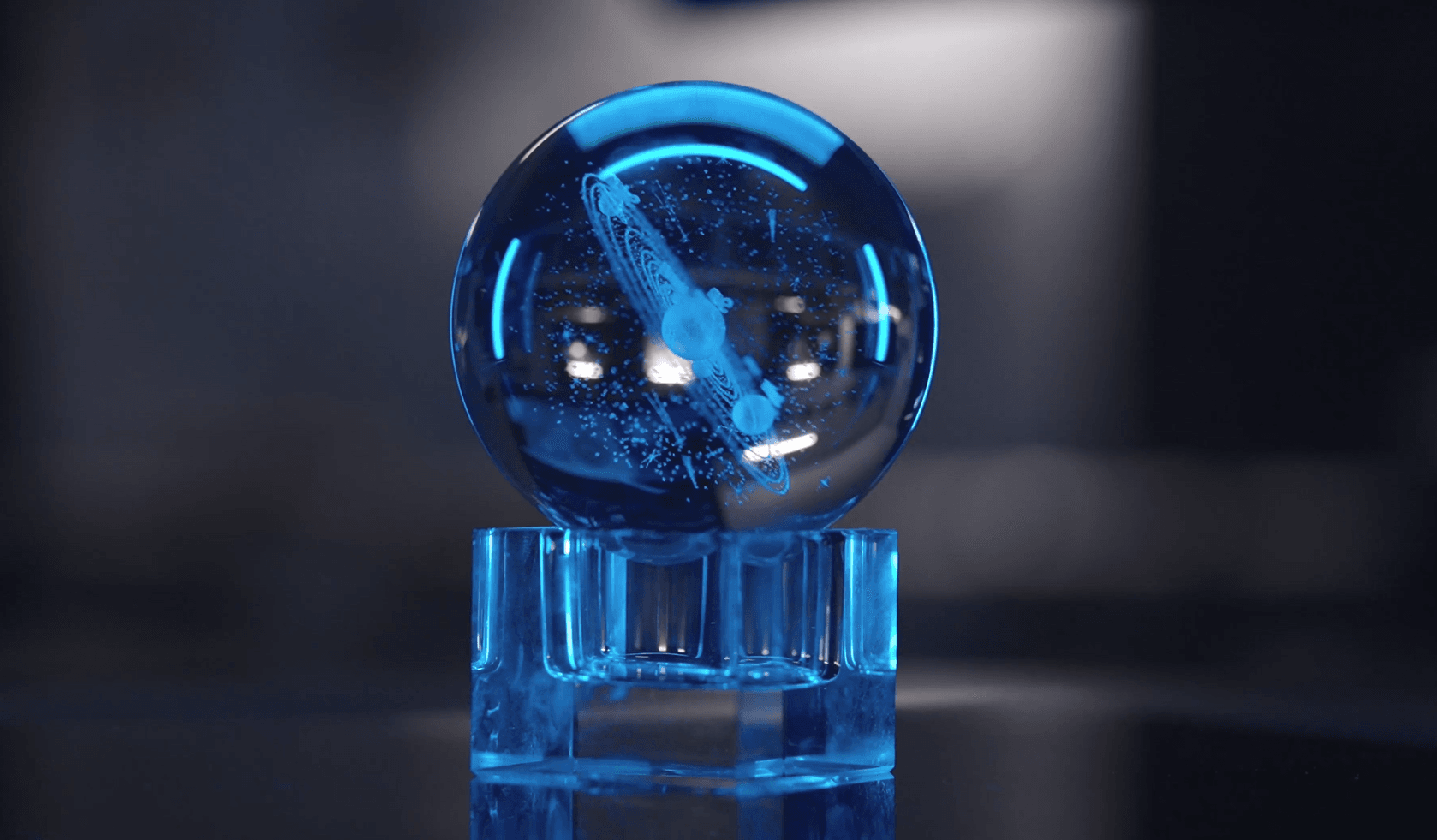

The first thing that hit me is that UV lasers have undergone a massive price collapse. Not long ago, a proper UV engraver — one capable of interior crystal engraving, the kind you see in mall kiosks where a dog or a child is magically suspended inside a crystal cube — cost eight to nine thousand dollars and more That was the barrier to entry. Today, we’re staring at machines in the $4,500 to $5,500 range. It’s practically half the price, and that price drop has sparked a rush of interest unlike anything I’ve seen since hobby CO₂ lasers first went mainstream. Suddenly UV is no longer an industrial luxury — it’s becoming a household tool, and people are stampeding toward it because they want fine detail, cold processing, and the ability to put memories inside K9 glass and that is just one of the options.

That brings me to the two machines left standing in my comparison. On one side is the xTool UV — a 5-watt system from a very polished marketing giant with a huge ecosystem. On the other side is the XlaserLab E3, a 10-watt UV engraver from a company that doesn’t merely brand lasers… it manufactures them. And that distinction became the anchor point in my decision. xTool is everywhere, but they based on my research are fundamentally a marketing and consumer-experience company first. I have searched for pictures of Xtool Factories but I can not find any. If you can find advertisements where they use them please tell me and I will change this, observation. This comment is based on my research.

See this VIDEO posted on Youtube for pictures of the Xlaserlab Facility.

XlaserLab, however, comes from industrial laser manufacturing. Before they entered the consumer UV engraving market, they were already building legitimate industrial hardware — including a laser welder that shows up repeatedly on YouTube because people like the welding quality, stability, and build construction. That is not white-label behavior. That is “we actually built this” behavior. And then there was this video that I have factored into my decision process thus far.

And UV engraving — especially interior crystal engraving — is not the kind of thing you want coming from a re-stickered chassis. It requires optical discipline, stable power regulation, consistent beam quality, and manufacturing precision. The more I looked at the pedigrees. One company is scaling up from the hobby world. The other is scaling down from the industrial world. And if you’ve spent any amount of time around lasers, you already know which direction tends to produce better machines. (My Opinion- Do your own research- I want everyone to get the best tool for their job.)

K9 Glass is not what is popular to put in the glass block, it is a type of Glass

K9 glass itself is a bit of a marvel once you realize what you’re actually holding. It’s not the same soda-lime glass you drink out of or bake a casserole in — this is an optical-grade borosilicate crystal made with barium oxide that gives it that almost water-clear appearance and smooth, uniform engraving behavior. The purity is the reason it reacts so beautifully under both CO₂ and UV beams: crisp, predictable, and none of the hidden bubbles or stress points that make household glass behave like it has emotional baggage. What’s funny is that for years K9 crystal used to be considered a “premium luxury item,” sold mostly as award blocks and corporate trophies, and priced accordingly. Now, thanks to the same global market forces that brought UV lasers down from nine grand to five, K9 crystal has followed suit — it’s everywhere. You can buy it on Amazon, AliExpress, Alibaba, trophy suppliers, and half the time you’ll find it at prices lower than basic drinkware. The combination of optical clarity, low cost, and the emotional punch it carries when engraved is exactly why it’s become the material of choice for interior crystal engraving and why the UV world is exploding around it.

Then there’s power.

xTool’s UV is 5 watts. The XlaserLab E3 is 10 watts. Twice the wattage matters more in UV than it does in CO₂ or diode engraving. With interior crystal work, you need to concentrate energy inside a piece of K9 glass to produce clean internal fractures. More wattage means deeper penetration, faster engravings, more detailed 3D imaging, and better handling of thicker blocks. It doesn’t just cut time in half — it opens the door to jobs that simply can’t be done with lower power. And with both machines living in the same general price neighborhood, choosing the one with twice the wattage feels less like an upgrade and more like common sense.!

LINK TO THE KICKSTARTER TO SEE PROGRESS!

But the decision wasn’t just about power or pedigree. I’m putting this machine in my house, and that makes safety and setup a huge part of the equation. One of the surprising advantages of UV lasers — especially at 355 nm — is that they are almost comically clean compared to CO₂ machines. UV engraving is often called a “cold laser” process because it vaporizes so little material that there’s barely any smoke or residue. For my intended use — engraving glass and crystal — there is zero smoke. Glass doesn’t burn. It doesn’t char. It doesn’t outgas. It just fractures microscopically. The only purifier I need is the same small one I already use for my fiber laser, and it’s more than enough.

This convenience gets even better when you consider the footprint. UV machines are tiny compared to CO₂ systems. No giant gantry. No 80-pound chiller. No ducting that looks like you’re storing HVAC equipment in your living room. A UV engraver fits neatly on a desk. And the XlaserLab E3, in particular, is a fully enclosed system. Close the lid, clip on a small purifier or inline filter, and you’ve basically created one of the cleanest laser setups you can run indoors. No floating smoke. No lingering smells. No open-frame exposure. It behaves more like a little appliance than a workshop tool.

By the time I layered all these factors together — the power, the optics, the manufacturing background, the enclosure, the cold-light processing, the zero smoke on glass, the tiny footprint, and the fact that the price crash has democratized UV — the path became clearer and clearer. The E3 isn’t just a tool; it’s a future-proof entry into where the laser market is heading. And interior crystal engraving isn’t a fad. Every sign shows it becoming the next premium category for small shops, makers, and anyone running a personalized-gift business. People love locking memories into glass — pets, portraits, memorials, wedding photos — and UV is the only wavelength that does that cleanly.

So after going through all of the research, the videos, the specs, the engineering details, the price trends, and the realities of running it safely in a house, I’m leaning strongly toward the XlaserLab E3. It gives me more power, more capability, more confidence, and more future options — all without asking for more money. It’s engineered, contained, stable, and ready for deep crystal work right out of the box. And as the UV market continues to evolve, I’d rather build my foundation on a machine made by a company that to me has proven they build the machines.

That’s where my decision stands today — informed, deliberate, and ready for the next chapter. And just like I said at the beginning, if you’re reading this for your own research, double-check everything. The laser world moves fast, specs change, prices shift, and new models appear out of nowhere. But based on what I know today, this is the direction I’m going… and I feel good about it.

If you have a different OPINION and want to share it send it to me at [email protected] Everyone has to do their own research to get the best machine for their job ,