OMG - what is a BLS Controller - Engraving inside Glass Block with UV

GK

**The Secret Behind 3D Crystal Engraving:

Why You Need a Special Controller (and Why LightBurn Won’t Work)**

Every few weeks, someone messages me a video of a floating 3D portrait locked inside a glass block and asks, “Hey George, can my UV laser do that?” And I always pause, take a deep breath, and try to decide whether to reply with engineering facts or a GIF of someone laughing into a pillow. Because here’s the truth: engraving on glass is one thing, but engraving inside glass—real 3D crystal engraving—is an entirely different universe governed by physics, point clouds, proprietary controllers, and manufacturers who treat their software like a state secret.

Before I go any further, let me say this clearly: I am not a laser expert. I’m just a guy doing professional-level due diligence because I refuse to spend thousands of dollars on a machine that turns into a paperweight the moment I look at it the wrong way. That said, I’ve learned enough to tell you that most of the videos you see online are showing off equipment you cannot replicate with an off-the-shelf UV galvo and a dose of optimism.

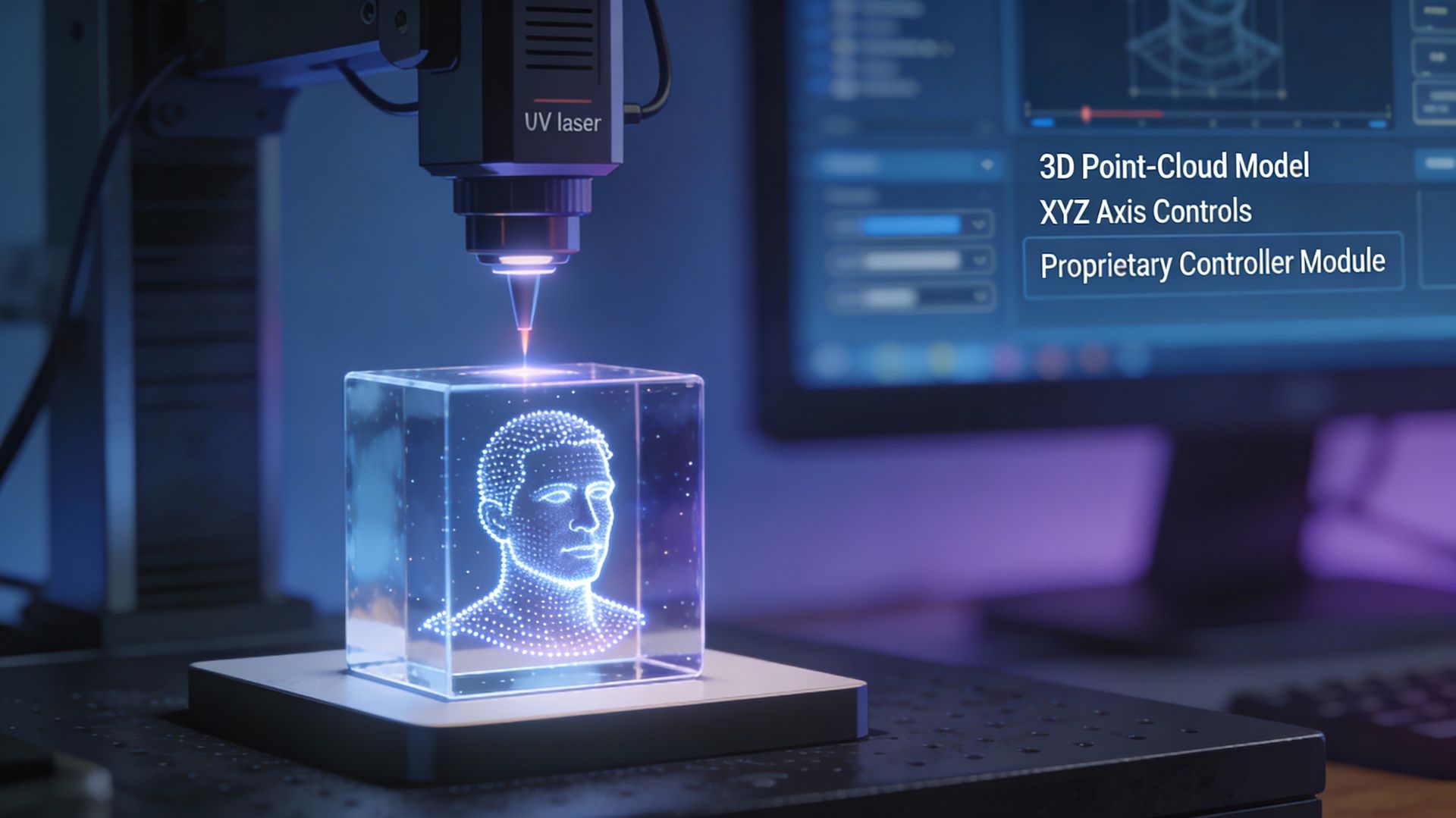

Here’s the part nobody tells buyers: real 3D subsurface engraving requires a controller that can position a laser beam at exact XYZ coordinates inside the glass, firing micro-explosions one at a time. It’s not a “raster” job, and it’s definitely not something LightBurn was ever designed to control. LightBurn is phenomenal—and I have written Article One’s worth of praise for it—but it’s a 2D and 2.5D design platform built for surface work. The moment you ask it to engrave a person’s face suspended three centimeters deep inside a block of crystal, it looks back at you politely and says, “Sir, that is not my ministry.”

And this is where our new villain enters the scene: the BSL controller. If you haven’t heard of it, that’s because you’ve been busy doing normal engraving like a sane person. The BSL controller is a strange creature used in dedicated 3D crystal machines. I did not go looking for this information; it simply attacked me one day during a conversation with a Haotien Laser manager, who casually mentioned, “Yeah, they use a BSL controller for interior engraving, but it doesn’t work well with LightBurn, so I don’t recommend it.” Translation: “This thing is great for internal crystal portraits, and terrible for everything else.” It’s the laser equivalent of buying a Ferrari that can only drive in reverse.

The BSL controller’s entire purpose is to read point-cloud files—the 100,000 to 3,000,000 tiny coordinates inside the block—and fire the laser with nanosecond accuracy to create microfractures suspended in the glass. That’s an impressive trick. But it comes at a cost: it speaks a completely different technical language from the EZCAD/Ruida/GRBL world where LightBurn lives. In other words, if you install a BSL controller in your workshop, say goodbye to LightBurn, your workflow, your familiar interface, and the 14,000 hours you’ve spent watching LightBurn tutorials at 2 a.m. You are now in a walled garden where the manufacturer owns the dirt, the fence, the seeds, and the fertilizer—assuming they’re still in business next year.

And here’s the part that really hurts: if I end up buying one of these machines, I will be breaking one of my own rules—a rule I carved into stone long ago: Do not buy any laser that is not compatible with LightBurn. Why? Because the moment you rely on proprietary software and proprietary hardware, you are tied to the manufacturer like a baby koala clinging to its mother. If that manufacturer folds, updates stop, drivers disappear, and suddenly you’re left with a $2,000–$10,000 crystal engraving machine that does nothing but collect dust and remind you of the day you betrayed LightBurn. Congratulations: you now own a laser-shaped boat anchor.

This is exactly why subsurface engraving remains such a specialized field. Crystal engraving companies protect their hardware and software stacks like they’re guarding a golden goose. They don’t want universality. They don’t want LightBurn compatibility. They certainly don’t want someone running their 3D crystal machines with open-source software. They want you locked into their ecosystem, where you buy their blocks, their software, their upgrades, and their hope.

Now, xTool and soon XLaser Labs are taking a different approach. They’re trying to make consumer-friendly versions of interior engraving, and to their credit, they’re actually marrying the hardware and the software into one cohesive package. But even they aren’t yet producing the point-cloud-driven, mall-kiosk-grade 3D crystal portraits you’re imagining. Not yet. Not without a controller class similar to BSL running quietly behind the curtain. They’re getting close, which is exciting, but not close enough for me to start practicing my “Your 3D portrait is ready, ma’am” sales pitch.

So is there a universal 3D point-cloud engraving platform on the horizon? Absolutely not. For that to exist, several things would need to happen: manufacturers would have to agree on a standard control language, standard data formats, standard depth-compensation models, and a shared understanding of how to manipulate refractive materials at scale. None of those companies have even agreed on what font to use in their manuals, so I wouldn’t hold your breath.

Here’s the bottom line: engraving inside glass is a niche category defined by secrecy, proprietary systems, and controllers that exist in a completely different evolutionary branch from our beloved LightBurn ecosystem. If you want to do real 3D crystal portraits, you need a machine designed from the ground up for that job—and if you buy one, you have to be comfortable knowing the software and hardware marriage is forever. Meanwhile, I’ll be over here wrestling with my conscience, because if I buy one of these machines, I’ll be violating my own Prime Directive: If LightBurn can’t run it, I probably shouldn’t either.

But hey—I’m not a laser expert.

I’m just a guy doing the due diligence no one else wants to do. If tyou have any information in this topic you want to share by all means contact me. I want to know more and if you have the information, that can answer these questions please let me know.

If you want to see more from the industry about engraving inside K9 Glass here is a great link. https://dekcel-cnc.com/blog/crystal-laser-engraving/