Why UV Lasers Are the Best for Glass Engraving

GK

Profits in Laser Engraving Glass: CO₂ vs. UV Lasers

IF you are considering engraving glass, this article may help you make the decision between CO₂ and UV lasers — here’s what separates the winners from the rest.

As a hobbyist who’s gradually turned “owning tools” into more of a lifestyle than a pastime, I get asked one question all the time: “If you were starting a laser business today, what machine would you buy first?” By the time someone reaches out, they’ve usually already convinced themselves they’re ready to hang out a shingle and start engraving for profit. I don’t usually argue with that—it’s their adventure, after all—but I do try to share something that doesn’t always get enough attention. Most people jump straight to wood, tumblers, or acrylic, but there’s a surprising profit center sitting quietly on the shelf that can set a business apart—glass engraving. Let's take a little deeper dive into laser engraving glass.

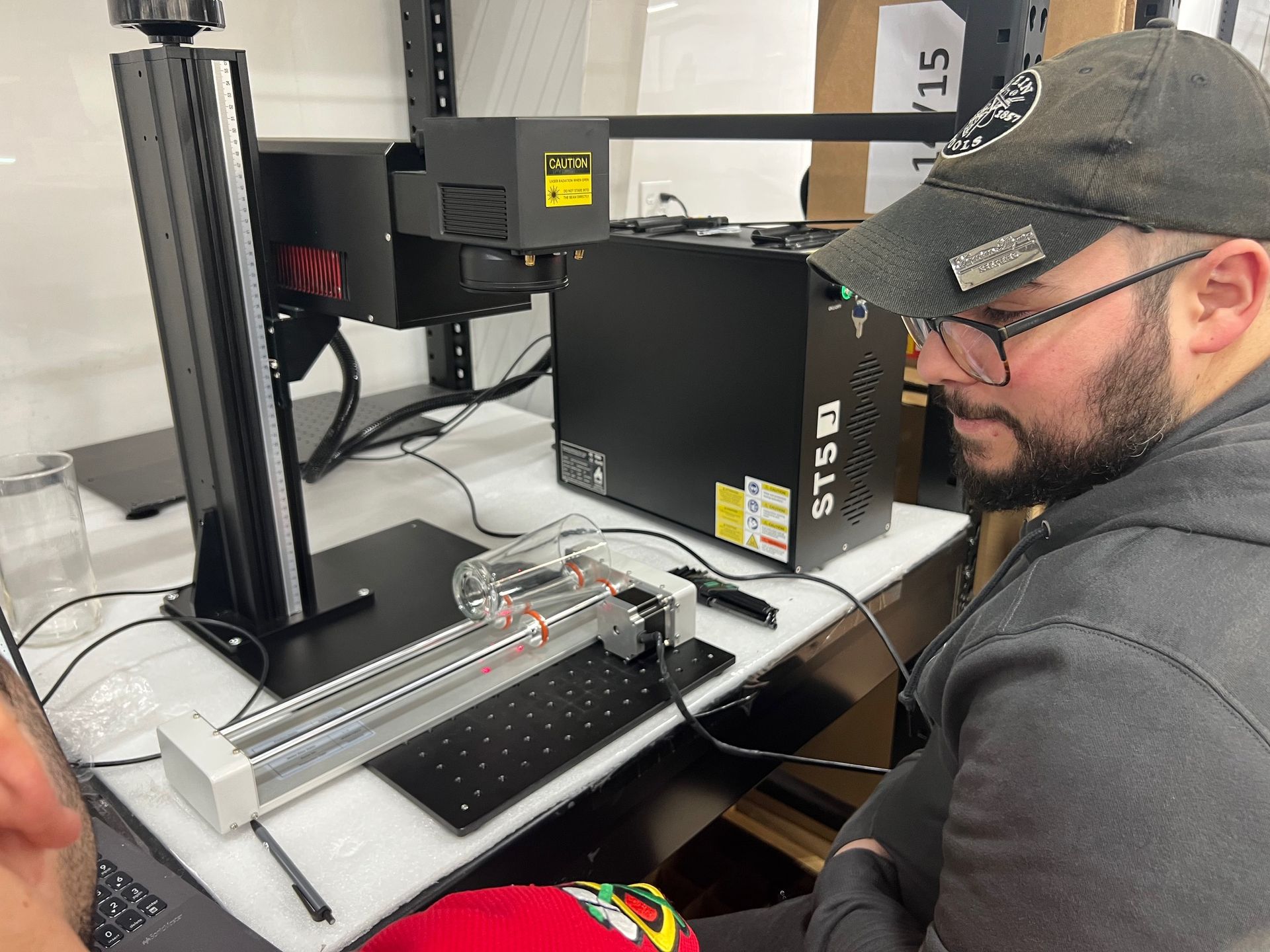

Why UV Lasers Are the Best for Glass

Here’s the part that might ruffle some feathers: if you want the best results on glass, the clear winner is the UV galvo laser. Yes, your trusty CO₂ can engrave glass. It’ll frost a wine glass, slap a logo on a bottle, and it’s fine for most entry-level work. But if you’re chasing clean detail, crisp logos, and consistent quality, CO₂ just can’t compete with what a UV can do. It’s like comparing a butter knife to a scalpel—both will cut, but only one makes you look like you know what you’re doing.

So why isn’t every engraver on the planet rushing out to buy a UV? Two reasons: price and laziness. UV systems have been on the expensive side, and let’s face it, most established engravers are already profitable with wood, acrylic, and tumblers. Learning another machine? Adding another workflow? That sounds dangerously like work. Which is exactly why the glass market is still wide open for the hungry new engraver willing to put in the time.

And here’s the kicker: because so many shops avoid it, glass engraving with UV is a perfect “missing profit center.” It’s the one thing most customers can’t get just anywhere, and that makes it the kind of opportunity that separates you from the pack.

Time: The Hidden Currency of Engraving

In the engraving world, the real profit isn’t hiding in your material cost—it’s in your time. Every extra minute you spend fiddling with a setup, cleaning shards of glass, or babying a process is a minute you’re not engraving the next job. Faster jobs = more throughput = more money. It’s not rocket science; it’s math.

This is where the UV laser shines. With CO₂, you often end up dealing with messy aftermath—chipping, flaking, cloudy edges—that either need a redo or a little post-production TLC. Some folks even swear you should engrave through vinyl masking and then sandblast the glass for “proper” results. Sure, if you enjoy adding hours of labor to every job, knock yourself out.

But with UV? It’s almost comical. You pull the glass out of the box, engrave it, and slide it right back in the box ready for delivery. No masking. No sandblasting. No cleanup crew. Just sharp, clean engravings that let you keep the conveyor belt of profits moving.

The golden rule is simple: never lose track of time. Because in engraving, the stopwatch is your real profit margin.

How to Think About Profit Without Chasing Price Tags

Now let’s talk about profit—but not in the “here’s your exact margin” way. I don’t believe in handing out cookie-cutter pricing charts because every market is different. What sells for $40 in a boutique gift shop might sell for $15 at a craft fair. What actually matters is knowing how to evaluate your own opportunity.

First, understand the investment. A solid UV laser is going to land somewhere in the $7,000–$10,000 range. That’s not pocket change, but it’s also not unreachable if you’re serious about turning engraving into a business. And unlike that treadmill you bought and never use, this tool can actually pay for itself.

Second, do the simplest and smartest bit of research you can: go buy a few engraved glasses. Pick up a custom pint glass, a wine glass, maybe even a small award piece. It’ll cost you less than $100, and in return you’ll get two things:

The actual product in your hands—so you can see the level of detail, quality, and finishing others are delivering.

A look at your competition—what they offer, how they present it, and what they’re missing.

That little exercise teaches you far more than any spreadsheet. It’s market research you can drink out of, and it costs less than taking the family to Applebee’s.

This is a great book to read if you are considering buyinig any Galvo style Laser, it covers the basics and does not mention any company names.

THIS IS A LINK TO THE BOOK

Plastics & Acrylics: UV lasers excel at marking plastics without burning or melting them, giving you clean edges and legible detail.

Electronics & PCBs: Permanent, fine markings on circuit boards.

Medical & Lab Equipment: Syringes, beakers, and other items where precision is non-negotiable.

Fine Detail on Metals: QR codes, micro text, and branding where clarity matters more than depth.

The bottom line? Glass may be the profit center that gets you in the door, but UV lasers pay for themselves many times over because they’re versatile. They’re the Swiss Army knife of precision marking—without the corkscrew you never use.

Speed and Support Matter Just as Much as the Machine

We’ve already talked about how time is the real currency of engraving, but let’s circle back to the machine itself. The speed of the UV laser you buy is going to directly impact your profits. A slower unit might look cheaper on paper, but if you’re sitting there waiting for it to crawl through a design while someone else’s machine is already onto glass number five, you’re losing money every hour it runs.

Equally important is who you buy the machine from. Multiple companies sell UV galvo systems, and while the core technology may be similar, the way each company approaches support, training, and warranty is not. One company might hold your hand through the first dozen jobs, while another might drop a crate on your driveway and wish you good luck. Knowing the difference before you spend thousands is worth its weight in gold.

And since we’re on that subject—I’ve actually written a book about buying a Galvo laser. At $5.95, it will be the best money anyone ever spends before diving into this side of the business. Whether you’re buying a fiber, CO₂ galvo, or UV system, the book walks through the questions you need to ask, the traps to avoid, and how to think like a buyer instead of a target. If you’re serious about making glass a profit center, it’s a no-brainer resource.

Wrapping It Up: The Only Math That Matters

At the end of the day, you don’t need a fancy spreadsheet or an MBA to decide if a UV laser is worth it. The math is simple enough for a napkin:

How many glasses do I need to engrave to pay off the machine?

If I fail, how much could I sell the laser for?

That’s it. Two simple formulas.

Here’s the kicker: good UV lasers are almost impossible to find used. I’ve been hunting for one myself, and they’re as rare as hen’s teeth. Why? Because people who own them aren’t letting them go. They’re too busy making money with them.

That’s the reality. UV isn’t just “another laser,” it’s the machine that unlocks glass profits (and a whole lot more) while most of your competition is still fiddling with masking tape and sandblasters. If you’re serious about building a laser business that stands out, the UV galvo deserves a spot at the top of your list.

A Special Thank You to EMP LASER Engineers and Laser Techs for allowing me to put one of there UV Lasers to the test.

EMP COURTSEY LINK - Just Click Here